|

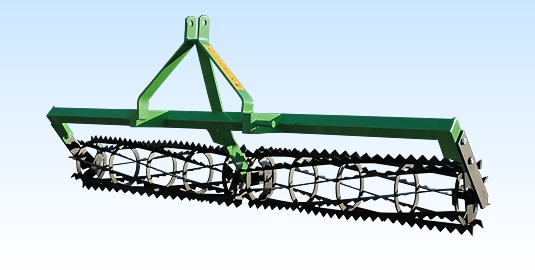

Disc harrows with 2 rollers (optionally: string or tubular roller)

Disc harrows is an implement designed for pre-seed tillage of heavy soil ploughed before winter season (beside stony fields) when the humidity ensure the proper working conditions. The disc harrow is also used for tearing and crushing of sod formation on the furrow – slice after ploughing on the meadows and other grasslands. It can be also used for stubble field skimming just after plant cutting. Disc harrow can also be used for the cutting and covering of manure and green manure (small and middle size) after its spreading. It is possible to apply the machine to mix fertilizers and lime with soil.

In the series of disc harrow with 2 rotors in the V arrangement there are two working widths of 1,5m and 2,7m. The coupling system that allows to couple the disc harrow with light string roller or heavy tubular roller is a standard equipment of the machine. The disc inclination angle adjustment in the range from 7° to 22° allows reaching proper working quality depending on variable working conditions and kind of soil. The discs with the diameter of 510 mm or 560 mm have been applied in disc roller. The attaching beam allows to increase disc harrow maintenance during its coupling.

Technical specification

Symbol

-

U363

U363/1

U363/3

U363/4

U363/7

U363/2

Working width

m

1,5

1,8

2,0

2,1

2,4

2,7

Working depth

mm

80 - 150

Number of sections

pcs

2

Number of discs

pcs

14

16

18

20

22

24

Machine weight

kg

350

370

420

555

580

620

Power demand

kW/HP

28/38

35/48

40/55

43/58

48/65

54/73

String roller diameter

mm

280

String roller weight

kg

100

125

135

140

160

180

Tubular roller diameter

mm

500

Tubular roller weight

kg

160

190

210

225

240

260

String roller diameter

mm

320

String roller weight

kg

160

170

180

195

215

230 Disc harrows is an implement designed for pre-seed tillage of heavy soil ploughed before winter season (beside stony fields) when the humidity ensure the proper working conditions. The disc harrow is also used for tearing and crushing of sod formation on the furrow – slice after ploughing on the meadows and other grasslands. It can be also used for stubble field skimming just after plant cutting. Disc harrow can also be used for the cutting and covering of manure and green manure (small and middle size) after its spreading. It is possible to apply the machine to mix fertilizers and lime with soil.

In the series of disc harrow with 2 rotors in the V arrangement there are two working widths of 1,5m and 2,7m. The coupling system that allows to couple the disc harrow with light string roller or heavy tubular roller is a standard equipment of the machine. The disc inclination angle adjustment in the range from 7° to 22° allows reaching proper working quality depending on variable working conditions and kind of soil. The discs with the diameter of 510 mm or 560 mm have been applied in disc roller. The attaching beam allows to increase disc harrow maintenance during its coupling.

Technical specification

Symbol

-

U363

U363/1

U363/3

U363/4

U363/7

U363/2

Working width

m

1,5

1,8

2,0

2,1

2,4

2,7

Working depth

mm

80 - 150

Number of sections

pcs

2

Number of discs

pcs

14

16

18

20

22

24

Machine weight

kg

350

370

420

555

580

620

Power demand

kW/HP

28/38

35/48

40/55

43/58

48/65

54/73

String roller diameter

mm

280

String roller weight

kg

100

125

135

140

160

180

Tubular roller diameter

mm

500

Tubular roller weight

kg

160

190

210

225

240

260

String roller diameter

mm

320

String roller weight

kg

160

170

180

195

215

230

|

Disc harrows is an implement designed for pre-seed tillage of heavy soil ploughed before winter season (beside stony fields) when the humidity ensure the proper working conditions. The disc harrow is also used for tearing and crushing of sod formation on the furrow – slice after ploughing on the meadows and other grasslands. It can be also used for stubble field skimming just after plant cutting. Disc harrow can also be used for the cutting and covering of manure and green manure (small and middle size) after its spreading. It is possible to apply the machine to mix fertilizers and lime with soil.

In the series of disc harrow with 4 rotors in the “V” arrangement there are two working widths of 2,7 m and 3,15 m. The coupling system that allows to couple the disc harrow with light string roller or heavy tubular roller is a standard equipment of the machine. The disc inclination angle adjustment in the range from 7° to 22° allows reaching proper working quality depending on variable working conditions and kind of soil. The discs with the diameter of 510mm or 560 mm have been applied in disc roller. The attaching beam allows to increase disc harrow maintenance during its coupling.

| ||||||

Disc harrows

Disc harrows with 4 rollers (optionally: string or tubular roller)

Disc harrows with 4 rollers (optionally: string or tubular roller)

| disc_harrows1.mht | |

| File Size: | 246 kb |

| File Type: | mht |

Title Text. Klik hier om te bewerken.

One-row potato planter mounted on the three point suspension system of tractor. The planter is mounted on the tractor with three point suspension system, CAT 1N. During single cycle all the activities concerning with potato planting are performed (it makes furrows, automatically seeds the potatoes and ridges the seeded plants with soil).

The potatoes can be planted at variable distance seed in a row (29 cm, 32 cm and 35 cm) in the metal wheels and a constant distance of 32 cm in the rubber wheels. Changing the distance of seed potatoes in a row of 29 cm by 32 cm to 35 cm can be achieved by changing the diameter of the wheels. Planting depth is 10 - 15 cm.

|

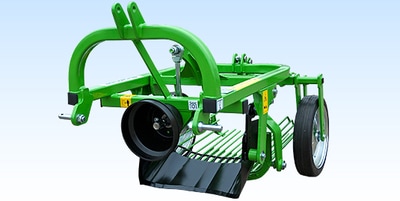

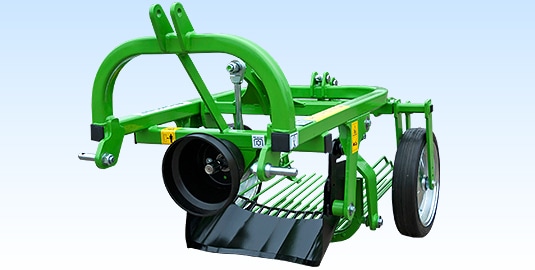

Vibrating digger with rear discharge can be mounted on small tractors equipped with the three-point suspension system of the I category. The machine consists of a vibrating ploughshare with adjustable digging depth that transfers potatoes and soil onto the vibrating hopper sifting potatoes from the soil. The digging depth is adjusted by rear support wheels. Sifting intensity can be increased by adjusting inclination of the sifting hopper.

All vibrating elements are moved by a crank mechanism driven from the tractor PTO shaft. Axes of the ploughshare and the sifting hopper are equipped with rubber bushings - simmerblocks which allow stability of the machine during operation. Its reduced dimensions enable to use the machine on small plots, flat and hilly areas. The digger can operate with mini-tractors with power of min. 10 HP.

Technical specification

Symbol

-

Z655/1

Number of rows

pcs

1

Width of the ridge

mm

450

Max working depth

mm

200

Machine weight

kg

135

Power demand

kW / HP

7,5 / 10 Vibrating digger with rear discharge can be mounted on small tractors equipped with the three-point suspension system of the I category. The machine consists of a vibrating ploughshare with adjustable digging depth that transfers potatoes and soil onto the vibrating hopper sifting potatoes from the soil. The digging depth is adjusted by rear support wheels. Sifting intensity can be increased by adjusting inclination of the sifting hopper.

All vibrating elements are moved by a crank mechanism driven from the tractor PTO shaft. Axes of the ploughshare and the sifting hopper are equipped with rubber bushings - simmerblocks which allow stability of the machine during operation. Its reduced dimensions enable to use the machine on small plots, flat and hilly areas. The digger can operate with mini-tractors with power of min. 10 HP.

Technical specification

Symbol

-

Z655/1

Number of rows

pcs

1

Width of the ridge

mm

450

Max working depth

mm

200

Machine weight

kg

135

Power demand

kW / HP

7,5 / 10

Vibrating digger (rear discharge)

| ||||||

Potato planter is two-row planter mounted on the three point suspension system of tractor. The planter is mounted on the tractor with three point suspension system, CAT 2. During single cycle all the activities concerning with potato planting are performed (it makes furrows, automatically seeds the potatoes and ridges the seeded plants with soil).

Potatoes can be planted in the interrows 62.5 / 67.5 cm or 70/75 cm at variable distances seed in a row (29 cm, 32 cm and 35 cm) in the metal wheels and a constant distance of 32 cm in the rubber wheels. Changing the distance of seed potatoes in a row of 29 cm by 32 cm to 35 cm can be achieved by changing the diameter of the wheels. Planting depth is 10 - 15 cm.

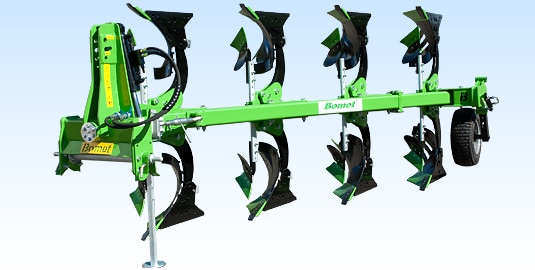

Disc ploughs of U040 series have a modular construction, i.e. they have the same structural elements but only differ in the number of bodies - discs and the size of the frame. Mounted ploughs available in our offer include 2-, 3-, and 4-disc ploughs with the working width of 0.6 m, 0.9 m and 1.2 m respectively. Disc ploughs are designed for ploughing on light, medium and heavy soils, are well prepared for operation on stony ground, meadows and wasteland up to 25 cm deep. The plough structure works particularly well in the cultivation of soil covered with plenty of plant remnants, compacted and very humus soils which usually clog mouldboard ploughs.

The ploughs are equipped with three-point suspension system of II category movably connected to the frame of the plough. This structure allows for smooth adjustment of the first furrow. To the main frame of the plough there are legs screwed on which working bodies - boron steel discs with a diameter of 660 mm are mounted. Legs have a step adjustment changing the approach angle of discs to improve the quality of ploughing and proper operation in various soil conditions. In addition, to adapt to various soil conditions, each disc is equipped with a smooth adjustment of the inclination angle by the eccentric bolt.

Ploughs are equipped with support wheels of a diameter of 480 mm and a width of 165 mm setting the working depth up to 25 cm. Spring thrust wheel mounted on the last body is designed to balance the lateral forces acting on the disc bodies.

Disc ploughs are suitable for aggregation with tractors equipped with suspension of II category with power from 41 hp to 82 hp.

|

Flail mower is a machine mounted on a tractor, equipped with three-point suspension system of the II category. Flail mower is mainly used for destruction of crop residues, for mulching meadows and pastures and for shredding cut branches of shrubs in soft fruit and fruit crops. The machine is perfectly suited to the orchard row crops where there is a need to move the machine axis in relation to the tractor axis. . Hydraulic side shift is optionally installed of max. 35 cm enables to avoid obstacles and avoid damage to plants by a tractor during the machine operation, e.g. in orchards.

Flail mower can be equipped with Y-type knives or hammers beaters. Y knives are designed for mowing grass, while flail knives are used for shredding small branches and bushes. During operation, the machine rests on two support wheels which owing to simple height adjustment allow to obtain appropriate shredding of the material.

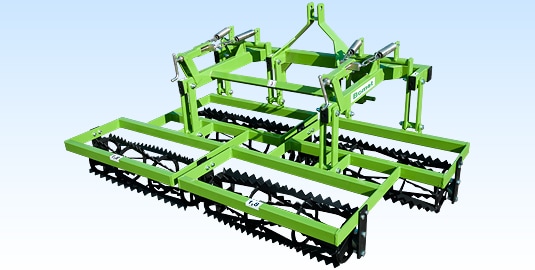

Power harrows are offered in four various types: for tractors of power up to 125 hp – harrows of width of 2.5 and 3.0 metres. This is a perfect solution since these machine are both stable and light. For tractors of power up to 165 hp, rotor harrows in versions 3.5 and 4.0 metres are the perfect match.

Power harrows are used for cultivation of soil after ploughing and for sewing on mulch, on loosened soil. Rack of the three-point suspension system is supported on large width and ensures optimal power transmission. Movable arms with lower coupling pins of 2 and 3 category ensure optimal levelling at the terrain inequalities between the tractor and the suspended machine. Strong and high gear trough with bulkheads ensures complete stabilization of the transmission beam. Cassette seal protects the machine against dust, moisture, dirt and extends the machine lifetime.

The central gearbox enables the change of rotor speed by setting the pair of cogwheels installed originally in the gearbox, in dependence on the required level of soil scarification.

Side deflectors have double action, as a shield against threat and as a side limiter for the treated soil and lumps. Side deflectors ensure equality of field treatment and prevent from making mounds on the connection of two crossings. In the working position the deflector needs to touch the field surface so that it is not damaged and its action is not limited. It should be immerged at approximately 10 mm.

Practical and user-friendly operation, fast aggregation with a tractor and soil well prepared for seeding are basic virtues of these agricultural machines. Serial equipment consists of a drive shaft, a packer roller or a tubular roller and a hydraulic coupling.

Owing to large space between the teeth, even much quantity of postharvest residues and soil lumps are treated without any difficulties. Due to strong construction, gear trough is resistant to long-lasting loading. Power harrows are perfect for aggregation with pressing shafts and seeders of our company.

When aggregating with a seeder, it is necessary to remember to reserve proper power supply and keep particular caution to the tractor controllability.

| ||||||||||||||||||||||||

|

Paragraph. Klik hier om te bewerken.

Frame ploughs Classic ploughs are designer for middle and deep ploughing of flat fields on every kind of soil (besides stony fields) when soil humidity enables proper work. In case of stony fields it is recommended to use plough with shear safety device which protects the machine body against damage.

The offer contains mounted ploughs that covers 2-, 3-, 4-, 5- furrow ploughs with body width of 250 mm, 300 mm and 350 mm. Ploughs are equipped with heavy duty, cylindrical mouldboards and plough shares. Over the mouldboard there is a special device that cuts top layer of soil and move it to the furrow bottom, what ensures better coverage of plant residues. Plough is equipped with screw device for adjustment of first furrow, working depth adjustment is carried out by steel or rubber supporting wheel. The legs of height 700 mm protects the plough from clogging while stubble field ploughing. In front of last body there is a special hole to fix the cutting disc, which is non standard equipment of the machine.

One-beam ploughs of U030 series are perfect for small and medium-sized farms in all soil conditions with tractors from 40 kM to 95 kM. The ploughs are intended for performing middle deep ploughing, on flat fields, slopes and hills on all types of soil. Spacing of bodies on the frame equaling 80 cm and clearance under the frame equaling 78 cm allows for unconstrained operation on fields with post-harvest residues.

The main unit of a plough is a bearing frame consisting of a coupler head and a hinged beam which enables alignment of the frame at changing the furrow width. The plough is equipped with three-point suspension system of category II. The frame beam with handles of plough bodies is connected with a coupler head of the frame with the use of pivots and an adjustment screw which sets the angle of inclination of the frame during alignment. 1-beam ploughs of U030 series are, as a standard, equipped with anti-stone protection in the form of a shear bolt, ensuring longer lifetime of the plough. In addition, each body can be equipped (additional option) with a skimmer or a disc coulter of diameter of Ø41 cm.

The profile of the main frame both for 2- and 3- furrow ploughs equals 100x100mm. For these models there is a possibility of installing an additional body (+1). The ploughing width is adjusted in steps for three positions (25 cm - 30 cm - 35 cm - for ploughs 16''). The adjustment is performed easily by proper switching of the adjustment screw on each body seat on the plough frame. The setting of the frame itself (alignment) for particular working widths is performed with the use of a turnbuckle. Small widths of the furrow are recommended during pre-sow ploughing, especially on heavy soils which require good crumbling. While large widths of the furrows are recommended to pre-winter ploughing, especially on light and medium soils.

In all models of the plough the adjustment of the first furrow is performed mechanically with the screw allowing for moving the slider along with the frame on the stationary ledger of the plough. A roller feeler setting the depth of ploughing up to 30 cm is mounted in the handle of the last body (as a standard).

Plough bodies of U030 series may be equipped with openwork mouldboards designed for heavy soils. Openwork mouldboards allow to reduce working resistance by 10% and thereby obtain lower fuel consumption.

The construction of the rotary head is adjusted for tractors of maximum power up to 95 hp. As a standard, there is a suspension system bracket with self-coupling mechanism. Owing to application of easy assembly of the lower coupling bar, mounting the plough with a tractor is easy and safe.

Series U064 reversible are perfect for medium and large farms in all soil conditions together with tractors between 55 hp to 130 hp. Ploughs are designed for medium bed-free ploughing on flat, sloping and hilly fields on all types of soils. The ploughs may be also used both for crops without pre-tilling and on fields after skimming. The spacing of bodies on the frame amounting to 90 cm and a clearance under the frame amounting to 78 cm allows to work comfortably on both high stubble fields and fields with harvest residues.

As a standard, series U064 reversible ploughs are equipped with stone protection in the form of a shear bolt which guarantees longer service life of a plough. Moreover, every body may be equipped with a skimmer or a disc coulter with a diameter of Ø41cm.

The profile of the main frame for both 3-furrow and 4-furrow ploughs is 120x120mm. For these models an additional body (+1) may be mounted. The ploughing width is adjusted in steps for three positions (30 cm – 38 cm – 45 cm - for ploughshares of 16'’). The adjustment is performed easily by switching the adjustment screw on each body seat on the plough frame in an appropriate way. The setting of the frame itself (alignment) for particular working widths is performed with the use of a turnbuckle. In all plough models the adjustment of the first furrow is performed mechanically with the screw allowing to move the slider together with the frame on the stationary ledger of the plough.

Series U064 plough bodies may be equipped with openwork mouldboards designed for heavy soils. Openwork mouldboards allow to reduce working resistance by 10% and thereby obtaining lower fuel consumption.

The construction of the rotary head is adjusted for tractors of maximum power up to 130 hp. A hitch bracket with a quick-coupling mechanism is standard equipment of a plough. Thanks to the application of the easily attached lower coupling beam, combining the plough with a tractor is easy and safe.

Ridging ploughs with attachment for ridge forming is designed for ridge forming on the potato plantation and vegetables planted in ridges. It cab used separately or with the attachment which forms and compacts the ridges. Ridging with attachment can only take place till the potato sprouting, because later the elements levelling the ridge can damage the plant.

Legs with spring tines that scarify the soil between the potato rows are fixed to the first beam of furrow plough frame. Skimming tines with coulter and potato rows ridging system are fixed to the second beam. The attachment that forms the final shape of ridges and limits the working depth of teeth is fixed to the rear attaching arms. Side working elements work only on the half of row what means that the furrow plough with working elements placed in three rows forms only two (two-row version) and four (four-row version) ridges. The width of cultivated rows can be adjusted in the rage of 62,5 cm to 75 cm.

The aggregate is intended for small and medium enterprises, owing tractors of average power. The main purpose of the aggregate is forming ridges in modern cultivation of potatoes and root vegetables. The machine is equipped with active and passive working units, enabling strip soil loosening and forming two broad and permanent ridges with the spacing of 75 cm or 67.5 cm. First, the soil is treated with passive tines, then with an active milling drum and the ridges are initially formed with the attachment with ridging bodies.

The machine covers two working versions which are distinguished by the arrangement of tines, copying wheels and tools forming the final shape of the ridges. In the version intended for ridging potatoes, the ridges are formed with a passive profiling attachment. In the version intended for cultivation of root vegetables, the ridges are formed with an active spool shaft. Both versions can be equipped with a seeder dosing the fertiliser directly into the ridges.

The forming and tilling aggregate is characterised by technical parameters corresponding to European standards in the field of operation and ergonomics safety. The aggregate is equipped with a set of shields preventing from throwing out stones and loosened soil, supports and protective barriers preventing from accidental access to the range of the milling drum. High quality and structural efficiency are gained as a result of using computer design methods; and the application of MES analysis enables solutions optimised for strength and durability.

Paragraph. Klik hier om te bewerken.

Hoe ridgers are multifunctional cultivation machines to apply for the tomato and other root crops planted in ridges. It can also be used on the vegetable, strawberry and maize plants. Hoe ridges can also be applied while weeds elimination process, row scarifying and aeration and ridging of rows with plants of height up to 60 cm.

The offer contains 2–rows or 4-rows tillage machines. The width of the cultivated rows can be adjusted in the range between 62,5 cm and 75 cm. Hoe ridges are equipped with knurls and hoes. Ridges are equipped with ridging body consisting of double side blade, mouldboard and two wings.

Rotavator is designed for opening and moving the soil without reversing. Moreover it is used for crushing clods, cutting of weeds, fast tilling after ploughing of meadows and pastures. Rotavator can be also used to mix fertilizers with soil on fields orchards and vegetable row cultivation. The advantage of the machine is the possibility to prepare soil for seeding up to 12 cm during single run on the field. The offer contains rotavators of working width from 1,2 m to 2,0 m.

Discs with angled knives are mounted on the rotor with interspace of 225 mm. The soil grinding is adjusted by movable rear protective guard. Raising the guard reduces soil grinding and lowering the guard increases soil grinding. Rotor rotating speed should amount 265 rpm. In order to drive rotavator, it is recommended to use PTO shaft with slip clutch to ensure operational reliability and durability of the machine.

Rotavator with cross traverse is designed for opening and moving the soil without reversing. Moreover it is used for crushing clods, cutting of weeds, fast tilling after ploughing of meadows and pastures. Rotavator can be also used to mix fertilizers with soil on fields orchards and vegetable row cultivation. The machine can also be used in glass house cultivation because of the possibility of traversing the machine axle in relation to the tractor axle. The advantage of the machine is the possibility to prepare soil for seeding up to 12 cm during single run on the field. The machine cross traverse that amounts 56 cm allows to avoid obstacles during the work, for example in orchards. The offer contains rotavators of working width from 1,4 m to 2,0m.

Discs with angled knives are mounted on the rotor with interspace of 225 mm. The soil grinding is adjusted by movable rear protective guard. Raising the guard reduces soil grinding and lowering the guard increases soil grinding. Knife rotating speed should amount 265 rpm. In order to drive rotavator it is recommended to use PTO shaft with slip clutch to ensure operational reliability and durability of the machine.

Universal seed drill U004 series is a new modern conception of the machine, arising from years of experience and continuous development of the construction. Typical working width of seeder 2,5 m - 2,7m - 3,0 m - 4,0 m allows you to connect them with other passive and active machines on the market. Driils are equipped with traditional, mechanical drilling system, with uncomplicated, durable construction and easy maintenance. Drills are particularly suitable for smaller farm on light and medium soils.

Seder can be used independently or in combination with passive or powered machines for soil cultivation, during sowing, sowing in mulch or after plowing. Taking into account the requirement for working in different soil conditions and cultivation methods, seed drill can be equipped with hoe coulters, single or double disc coulters.

Hopper with a bottom in the shape of „V” ensures a complete emptying from the seed. Seed devices are driven by two gear wheels, chain transmission and 60-position variable-speed transmission.

Standard version of seeder is equipped with hydraulic markers and platform ensuring easy load of hopper. Additionally, seeder can be equipped witch electric switch of technological patch, tractor track rippers and electronic hectare counter to monitor how many hectares have been sown.

|

Classic ploughs are designer for middle and deep ploughing of flat fields on every kind of soil when soil humidity enables proper work. In case of stony fields it is recommended to use plough with shear safety device which protects the machine body against damage.

The offer contains mounted ploughs that covers 2-, 3-, 4-, 5- furrow ploughs with body width of 250 mm, 300 mm and 350 mm. Ploughs are equipped with heavy duty, cylindrical mouldboards and plough shares. Over the mouldboard there is a special device that cuts top layer of soil and move it to the furrow bottom, what ensures better coverage of plant residues. Plough is equipped with screw device for adjustment of first furrow, working depth adjustment is carried out by steel or rubber supporting wheel. The legs of height 700 mm protects the plough from clogging while stubble field ploughing. In front of last body there is a special hole to fix the cutting disc, which is non standard equipment of the machine.

Single-beam ploughs (width of body: 0,30 –> 0,50)

Single-beam ploughs are designed for medium and deep ploughing on various soils. If stony soils occur, ploughs with spring stone release system which effectively protect against the overload and damage are recommended.

The main unit of a plough is a bearing frame which consists of coupler head and hinged beams. It enables to adjust the furrow width.

3 point linkage cat. 3 or 4 enabling the connection of the plough to the tractor consists of a cross shaft with a headstock supported by a long bracket.

3 point linkage is equipped with two adjusted screws which allow to adjust the width of the first furrow width (lateral adjustment) and the pressure of body skids on furrow walls (longitudinal adjustment).

Beams of a frame with handles of plough bodies are connected with a headstock of the frame by bolts and screws (setting the angle of inclination). Adjustment of the linkage in relation to the first body is adapted to classical ploughing.

Plough body beam is mounted in the handle of a frame with a pin and a spring which protect them from overloading. Working width of plough bodies is adjustable from 0.3 to 0.5 m.

Longitudinal spacing of plough bodies is 900 mm which together with high ground clearance under the frame (830 mm) provide high resistance to plant residue clogs. Gauge wheel which sets the depth of ploughing in the range from 0 to 350 mm is mounted in the holder of the third plough body.

Additional option are disk skimmers providing for good quality (uniform and shallow) of ploughing the organic matter. Any other manufacturers do not have such an offer. Disc skimmers are attached to the beam of bodies with the aid of holders to allow free adjustment of working parts of the body.

Small widths of the furrow are recommended during pre-sow ploughing, especially on heavy soils which require good crumbling. Large widths of the furrows are recommended to pre-winter ploughing, especially on light and medium soils.

Reversible ploughs (width of body: 0,25 - 0,30 - 0,35)

Series U063 reversible ploughs are perfect for medium and large farms in all soil conditions together with tractors between 40 hp to 105 hp. Ploughs are designed for medium bed-free ploughing on flat, sloping and hilly fields on all types of soils. The ploughs may be also used both for crops without pre-tilling and on fields after skimming. The spacing of bodies on the frame amounting to 90 cm and a clearance below the frame amounting to 71 cm allows to work comfortably on both high stubble fields and fields with harvest residues.

As a standard, series U063 reversible ploughs are equipped with stone protection in the form of a shear bolt which guarantees longer service life of a plough. Moreover, every body may be equipped with a skimmer or a disc coulter with a diameter of Ø41cm. The profile of the main frame for both 2-furrow and 3-furrow ploughs is 100x100mm. For these models an additional body (+1) may be mounted. The ploughing width is adjusted in steps for three positions (25 cm – 30 cm – 35 cm - for ploughshares of 16''). The adjustment is performed easily by switching the adjustment screw on each body seat on the plough frame in an appropriate way. In all plough models the adjustment of the first furrow is performed mechanically with the screw allowing to move the slider together with the frame on the stationary ledger of the plough.

The construction of the rotary head is adjusted for tractors of maximum power up to 105 hp. A hitch bracket with a quick-coupling mechanism is standard equipment of a plough. Thanks to the application of the easily attached lower coupling beam, combining the plough with a tractor is easy and safe.

Mounted reversible ploughs of U052 series are perfect for small and medium-sized agricultural holdings, for all soil conditions, for tractors from 75 hp to 150 hp. Ploughs of U052 series are intended for performing middle deep and deep bed free ploughing, on flat fields, slopes and hills on all types of soil. The ploughs can be used at crops without pre-tilling, and also on fields after skimming. Due to a large spacing of bodies on the frame equalling 100 cm and large clearance under the frame equalling 78 cm, the reversible ploughs are perfect on high stubbles and also on fields with post-harvest residues.

Reversible ploughs of U052 series are, as a standard, equipped with a system of non-stop protection against stones (suspension spring), ensuring longer lifetime of the plough. As a standard, each body is protected with 5 leaves, which comprises protection at the power of 900 kg on the ploughshare coulter. Ploughs can also be equipped with a system using shear bolts; such protection is recommended on stoneless fields.

The profile of the main frame both for 3- and 4- furrow ploughs equals 140x140mm. For these models there is a possibility of installing an additional body (+1). The ploughing width is adjusted in steps for three positions (34 cm – 42 cm – 50 cm - for ploughs of 18''). The adjustment is performed easily by proper switching the adjustment screw on each body seat on the plough frame. In all models of the plough the adjustment of the first furrow is performed mechanically with the screw allowing for moving the slider along with the frame on the stationary ledger of the plough.

The construction of the rotary head is adjusted for tractors of maximum power up to 150 hp. Rotation axis of 125 mm ensures maximum strength and durability. As a standard, there is a suspension system bracket with self-coupling mechanism. Owing to application of easy assembly of the lower coupling bar, mounting of the plough with a tractor is easy and safe.

The cultivator has been designed for the soil opening, crushing of clods, weeds undercutting and mixing fertilizers with soil. It is recommended to use cultivator on the stubble field to stop evaporating water from soil.

The offer contains cultivators tines fixing on clamping rings. Cultivator tines are ended with easy changeable coulters. Tines are fixed to the frame in the three rows with interspace of 140 mm by means of yoke screws. The basic equipment of the machine are two supporting wheels that set machine working depth.

Single-beam ploughs (width of body: 0,30 - 0,38 - 0,45)

Series U031 single-beam ploughs are perfect for medium and large farms in all soil conditions together with tractors between 55 hp to 130 hp. Ploughs are designed for medium and deep ploughing on flat, sloping and hilly fields on all types of soils. The spacing of bodies on the frame amounting to 90 cm and a clearance under the frame amounting to 78 cm allows to work comfortably on both high stubble fields and fields with harvest residues.

The main bearing unit of the plough is a bearing frame consisting of a headstock and an inclining beam which allows frame alignment when adjusting the furrow width. The plough is equipped with a category III three-point hitch. The frame beam with handles of plough bodies is connected with a frame headstock with bolts and an adjusting screw which sets the angle of frame inclination during the alignment.

As a standard, series U031 single-beam ploughs are equipped with stone protection in the form of a shear bolt which guarantees longer service life of a plough. Moreover, every body may be equipped with a skimmer or a disc coulter with a diameter of Ø41cm.

The profile of the main frame for both 3-furrow and 4-furrow ploughs is 120x120mm. For these models an additional body (+1) may be mounted. The ploughing width is adjusted in steps for three positions (30 cm – 38 cm – 45 cm - for ploughshares of 16'’). The adjustment is performed easily by switching the adjustment screw on each body seat on the plough frame in an appropriate way. The setting of the frame itself (alignment) for particular working widths is performed with the use of a turnbuckle. Small widths of the furrow are recommended during pre-sow ploughing, especially on heavy soils which require good crumbling. On the other hand, large widths of the furrow are recommended during pre-winter ploughing, especially on light and medium soils.

In all plough models the adjustment of the first furrow is performed mechanically with the screw allowing to move the slider together with the frame on the stationary ledger of the plough. A roller feeler setting the depth of ploughing up to 35 cm is mounted in the handle of the last body (as a standard). Series U031 plough bodies may be equipped with openwork mouldboards designed for heavy soils.

Openwork mouldboards allow to reduce working resistance by 10% and thereby obtaining lower fuel consumption.

The construction of the rotary head is adjusted for tractors of maximum power up to 130 hp. A hitch bracket with a quick-coupling mechanism is standard equipment of a plough. Thanks to the application of the easily attached lower coupling beam, combining the plough with a tractor is easy and safe.

The cultivator has been designed for the soil opening, crushing of clods, weeds undercutting and mixing fertilizers with soil. It is recommended to use cultivator on the stubble field to stop evaporating water from soil.

Light cultivator teeth are ended with easy changeable coulters. Tines are fixed to the frame in the four rows with interspace of 140 mm by means of retaining straps. The basic equipment of the machine are two supporting wheels that set machine working depth.

The mechanical mounted seed drills is a modern construction based on many years of experience and continuous development. Top seed drills are in typical widths of 2.5 m and 3.0 m enabling assembly with a power harrow. These are easy to use seed drills with traditional mechanical seeding system, with a simple, durable construction.

Mechanical seed drill mounted on a power harrow depending on soil conditions can be equipped with hoe coulters, single- or double disc coulters. Single- or double-disc coulters can be optionally equipped with copying wheels. The main task of copying wheels is to maintain proper seeding depth and soil compaction over the sown grain. Soil compaction results in better access to moisture especially on sandy soils, which is very important at spreading small-seed plants e.g. rape. This affects obtaining faster and more equal emergence of sown crops.

Connection of the seed drill with a power harrow is performed by a special bracket installed on the arm mounting the tillage roller of the power harrow.

Seed hopper with "V"-shaped bottom provides complete emptying of the seed. Drive of sowing units is performed by the drive wheel, chain transmission unit and the 60-position variable transmission.

The mounted seed drills is, as a standard, equipped with hydraulic track markers and a platform for easy loading the hopper. Power-operated tramlines can be the additional optional equipment of the seed drill. Moreover, this seed drill can be equipped with pre-emergence markers.

Skimming units is designed for after crop tillage in order to prepare field for standard cultivation. Skimming units with tubular roller are also available in the offer. Skimming units with tubular roller are designed to be used on the heavy, firm soils and while maize growing.

Technical data and parameters fulfils European standards in the range of usage and service safety and ergonomics. High efficiency is a result of applying the newest computer-aided design methods. Optimal lifetime and strength has been reached thanks to a design parametric modeling with 3D system and versatile design analysis MES systems.

Skimming roller are equipped with drill shoe with undercutting device. It provides deeper mixing plant residues with soil. Wide tine interspace of 42,5 cm and 65 cm distance between frame and ground level enable smooth work on the field covered with plant residues. The screw safety device prevents from running onto an obstacle. Leveling discs fastened on the deflecting frame of the roller are advantageous because of overload absorbing and tracking the roller position. The roller enables also setting the Tillage outfit working depth up to 15 cm.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Two row string roller can be coupled with other implements like cultivator or harrow what composes tillage outfit. The advantage of coupling two tillage implements into one set is the possibility of having well prepared field to seeding or sowing after single run on the field. Thanks to the decrease of number of field run passes it is possible to avoid soil compaction by tractor wheels. The second advantage is a decrease of soil cultivation costs. The string roller causes insignificant soil compaction and applying the toothed bar ensures well crushed upper soil layer. The field pass of this kind of roller leaves thin, well crushed soil over the layer of slightly compacted soil. String rollers especially well prepare the field to the pointwise seeding (for ex. beets, maize, vegetables).

The offer contains two row string rollers with diameter 295 mm fitted to cultivator working width from 1,8m to 3,6m. The standard equipment contains screw type fastener that sets roller working depth. Holders for triangle plate and lights are fixed to the string roller frame.

|

Two-row string rollers with clamping can be used as an independent machine or combined with other machines (e.g. a cultivator) and create soil cultivation sets. The advantage of combining two tillage tools into one set is that a well-prepared field for seeding or sowing is obtained after one pass. Thanks to the decrease of number of field passes, tractor wheels do not destroy the aggregated structure of the soil, soil packing is reduced, and soil cultivation and additional tillage costs are reduced significantly. The string roller causes insignificant soil packing and toothed bars allow to crush the upper soil layer very well. The field pass of this kind of a roller leaves a thin, well crushed soil over the layer of slightly packed soil. String rollers especially well prepare the field for point seeding (e.g. beet, maize, vegetables).

The working elements of the string roller may be set in a frame on bearings or on sleeves. The frame with the working elements is mounted to the main frame through the parallelogram. Roller pressure is adjusted with springs mounted to the main frame and the parallelogram. The main frame with a three-point hitch allows to combine the rollers with a tractor on one’s own, and the rollers may be combined with a cultivator through the very same three-point hitch, creating a soil cultivation set.

The offer includes two-row string rollers with a diameter of 295 mm suitable for typical working widths of cultivators. A screw connector joining the string roller with the cultivator is included in standard equipment.

| ||||||||||||

Subsoilers is designed only for deep scarifying of soil. The harrow that works with plough, rakes and levels off the soil what limits evaporating water from ground and makes faster growing seeded plants. The process should be applied on the field with ploughed soil, after harvest time when the soil is dry. In order to avoid too excessive soil compaction next soil processing should not be done in too short period of time on the ploughed field. Subsoilers can also be used to prepare the soil before planting fruit trees, berry bushes and plants with deep root system.

Technical data and parameters fulfils European standards in the range of usage and service safety and ergonomics. High efficiency is a result of applying the newest computer-aided design methods. Optimal lifetime and strength has been reached thanks to a design parametric modeling with 3D system and versatile design analysis MES systems.

Subsoilers is built of the tough frame, on which working elements – long plough beam tines – are mounted. The offer contains subsoiler with one - tine, two - tine, there - tine and four tine chisel plough with tine interspace of 75 cm. the effective working depth of chisel plough is 45 cm. About 30 kW per one tine is requested to guarantee proper subsoiler work quality and efficiency.

|

Single row string roller can be coupled with other machines like cultivator or harrow what composes tillage outfit. The advantage of coupling two tillage implements into one unit is the possibility of having well prepared field to seeding or sowing after single run on the field. Thanks to the decrease of number of field run passes it is possible to avoid soil compaction by tractor wheels. The second advantage is a decrease of soil cultivation costs. The string roller causes insignificant soil compaction and applying the toothed bar ensures well crushed upper soil layer. The field run pass of this kind of roller leaves thin, well crushed soil over the layer of slightly compacted soil. String rollers especially well prepare the field to the pointwise seeding (for ex. beets, maize, vegetables).

The offer contains single-row string rollers with diameter 295 mm fitted to cultivator working width from 1,8m to 2,8m. The standard equipment contains screw type fastener that sets roller working depth. Holders for triangle plate and lights are fixed to the string roller frame.

| ||||||

| subsoilers__working_depth_to_45_cm_.pdf | |

| File Size: | 316 kb |

| File Type: | |

|

Paragraph. Klik hier om te bewerken.

|

Paragraph. Klik hier om te bewerken.

|

|

| ||||||||||||

Paragraph. Klik hier om te bewerken.

Cultivating units with seeding function are designed for simultaneous cultivation soil and seeds. These units can be used for preseed soil cultivation after seed or pre-winter ploughing. It is also possible to use this cultivating unit to preparing the soil in reduced technologies of seedbed cultivations.

Cultivating units with seeding functions are equipped with universal main frame. On that frame, there are attached 2 or 3-rows cultivator and roller that compacts soil. Cultivator is equipped with tines with changeable reversible cultivator point. Behind these elements, there are mounted tubular roller or packer roller that compacts scarified soil. Cultivators position is fixed, and working depth is adjusted by supporting wheels and rear roller position.

Cultivating units are equipped with hydraulic coupling for the seeder with II and III cat. linkage system.

As a non standard equipment of cultivating unit, it is provided to use front mounted implement that is attached to the front 3-point coupling system of tractor. The front implement base is a ballast box with two double wheels. Leveling harrow or 2-row cultivator are mounted to the ballast box.

Technical data and parameters fulfils European standards in the range of usage and service safety and ergonomics. High efficiency is a result of applying the newest computer-aided design methods. Optimal lifetime and strength has been reached thanks to a design parametric modeling with 3D system and versatile design analysis MES systems.

Indisputable advantages of cultivating units are time and fuel economy with simultaneous soil protection thanks to reducing the number of tractor coupled with cultivating unit field drive passes. Front mounted implement that is optionally used (non standard equipment) in the cultivating unit improves tractor working stability during work and transport. Work with attached front implement is more efficient because of ability to work with higher working speed when the field ahead tractor is leveled.

Tilling sets is designed for either preparing soil to the sowing operations or planting during single course. Moreover, it is used for crushing clods, breaking up the crusted soil and cutting of weeds. Tilling sets can also be used to mix fertilizers with soil on fields. Usage of connected machines enables reducing number of field drive passes simultaneously ensuring proper soil cultivation and reducing negative impact on the soil and saving costs of operation.

Tilling sets is composed of two tilling implements - cultivator that can be coupled with rear one or two-row toothed string roller. Implement tines are mounted in four rows, with 100 mm interspace. Each tine is equipped with easily changeable coulter. Rear-mount 1 or 2-row toothed string roller with diameter of 295 mm is mounted on with the bushing or bearing.

In order to make easier coupling with tractor cultivator unit can be equipped with attaching beam. Despite of working width exceeding 3.0 m, tilling sets can be transported on public roads because of manually foldable arms. Portable warning - lights system and slow speed vehicles triangle plate are standard equipment what allows to transport machine on public roads.

illing sets is designed for either preparing soil to the sowing operations or planting during single course. Moreover, it is used for crushing clods, breaking up the crusted soil and cutting of weeds. Tilling sets can also be used to mix fertilizers with soil on fields. Usage of connected machines enables reducing number of field drive passes simultaneously ensuring proper soil cultivation and reducing negative impact on the soil and saving costs of operation.

Tilling sets is composed of two tilling implements - cultivator that can be coupled with rear one or two-row toothed string roller. Tilling sets tines are mounted in four rows, with 100 mm interspace. Each tooth is equipped with easily changeable coulter. Rear-mount 1 or 2 row toothed string roller with diameter of 295 mm is mounted on the with bushing or bearing.

In order to make easier coupling with tractor cultivator unit can be equipped with attaching beam. Portable warning - lights system and slow speed vehicles triangle plate are standard equipment what allows to transport machine on public roads.

|

Heavy tilling sets of U985 series are machines, which during one passage prepare the soil perfectly for sowing in various soil conditions. Two rows of spring tines ended with wide cultivator points, which are attached to the intermediate frame are the main working components of the unit. Depending on the working width, the units are equipped with 10 tines with the working width respectively of 2.5 m, 12 tines for the unit of 3.0 m and 16 tines for the unit of 4.0 m. By attaching cultivator points on the spring legs, the soil is undercut and well mixed. Through the use of a parallelogram mechanism, the intermediate frame determines precisely the working depth of the tines in relation to the rollers in the range of 2 cm to 12 cm. Lateral deflectors are used in the unit in order to reduce scattering soil beyond the working width of the machine.

The front string roller with a diameter of 370 mm and a front crushing bar facilitate operation on compacted and lumpy soils.

At the back the unit can be equipped with a crosskill roller with a diameter of 350 mm or a string roller with a diameter of 370 mm. The rear harrow is the end component of the unit. The rear crosskill roller, recommended for heavy and compacted soils, crushes and crumbles lumps and also leaves the field surface a little scarified. The rear string roller will be perfect on lighter and less compacted soils. Application of the rear harrow leveling and compacting the field surface gently provides an excellent seedbed preparation.

Units are adjusted for aggregation with tractors equipped with suspension system of II and III category with power from 100 hp to 165 hp.

Tilling sets is designed for either preparing soil to the sowing operations or planting during single run on the field. Moreover, it is used for crushing clods, breaking up the breaking up the crusted soil and cutting of weeds. Tillage outfits can also be used to mix fertilizers with soil on fields. Usage of connected machines enables reducing number of field drive passes simultaneously ensuring proper soil cultivation and reducing negative impact on the soil and saving costs of operation.

Tilling sets is composed of two tilling implements - cultivator that can be coupled with rear one or two-row toothed string roller. Tilling sets tines are mounted in four rows, with 100 mm interspace. Each tooth is equipped with easily changeable coulter. Rear-mount 1 or 2 row toothed string roller with diameter of 295 mm is mounted on with the bushing or bearing.

In order to make easier coupling with tractor cultivator unit can be equipped with attaching beam. Tilling sets with big working width is equipped in hydraulic system that enables arms folding. Portable warning - lights system and slow speed vehicles triangle plate are standard equipment what allows to transport machine on public roads. Tilling sets with front roller is recommended to use on heavy soil with many clods that are crushed and crumbled by front roller.

illing sets is designed for either preparing soil to the sowing operations or planting during single course. Moreover, it is used for crushing clods, breaking up the crusted soil and cutting of weeds. Tilling sets can also be used to mix fertilizers with soil on fields. Usage of connected machines enables reducing number of field drive passes simultaneously ensuring proper soil cultivation and reducing negative impact on the soil and saving costs of operation.

Tilling sets is composed of two tilling implements - cultivator that can be coupled with rear one or two-row toothed string roller. Tilling sets tines are mounted in four rows, with 100 mm interspace. Each tooth is equipped with easily changeable coulter. Rear-mount 1 or 2 row toothed string roller with diameter of 295 mm is mounted on with the bushing or bearing.

In order to make easier coupling with tractor cultivator unit can be equipped with attaching beam. Tillage outfits of big working width is equipped in hydraulic system that enables arms folding. Portable warning - lights system and slow speed vehicles triangle plate are standard equipment what allows to transport machine on public roads.

Tilling sets with front roller is recommended to use on heavy soil with many clods that are crushed and crumbled by front roller.

| ||||||||||||||||||||||||||||||||||||

Tilling sets is designed for either preparing soil to the sowing operations or planting during single run on the field. Moreover, it is used for crushing clods, breaking up the crusted soil and cutting of weeds. Tilling sets can also be used to mix fertilizers with soil on fields. Usage of connected machines enables reducing number of field drive passes and additionally ensuring proper soil cultivation and reducing negative impact on the soil and saving costs of operation.

Tilling sets is composed of two tilling implements - cultivator that can be coupled with rear one- or two-row toothed string roller. Tilling sets tines are mounted in four rows, with 100 mm interspace. Tines are equipped with easily changeable coulters. Rear-mount one- or two- row toothed string roller with diameter of 295 mm is mounted on with the bushing or bearing.

In order to make easier coupling with tractor, cultivator unit can be equipped with attaching beam. Portable warning - lights system and slow speed vehicles triangle plate are standard equipment what allows to transport machine on public roads.

Tilling sets with front roller is recommended to use on heavy soil with many clods that are crushed and crumbled by front roller.

| tilling_sets_with_front_roller.pdf | |

| File Size: | 232 kb |

| File Type: | |